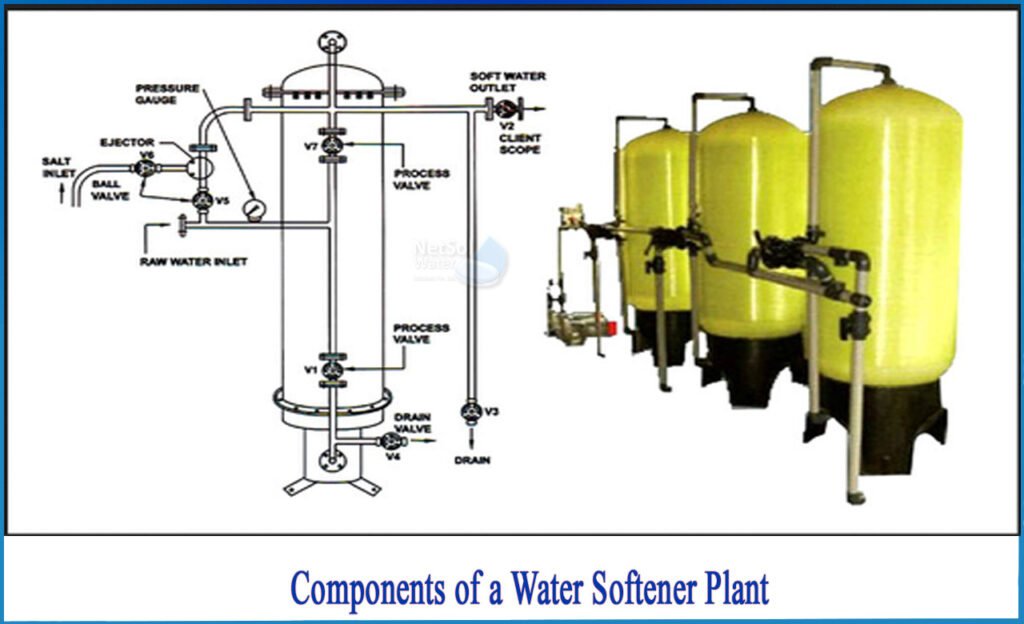

Our Softening Plants Systems service provides modern methods to reduce water hardness by eliminating calcium, magnesium, and other minerals that cause scale buildup in pipes, appliances, and industrial equipment. These systems are critical for both residential and industrial applications, where soft water is required for efficient operation and equipment longevity.

Process Overview:

Water softening is the process of exchanging hardness-causing minerals for sodium or potassium ions, which is primarily accomplished through the use of ion exchange technology. The resulting soft water inhibits scale formation, increases soap efficiency, and lowers scaling-related maintenance expenses.

Details:

Raw Water Intake:

Source Water: Water from municipal supply, wells, or other sources is first collected and assessed for hardness levels. The effectiveness of the softening process depends on accurately determining the initial hardness of the water.

Pre-Treatment:

Sediment Filtration: Before softening, water may pass through sediment filters to remove suspended solids, which can protect the softening system and improve its efficiency.

Activated Carbon Filtration (if needed): In some cases, activated carbon filters are used to remove chlorine, organic compounds, or other impurities that could affect the ion exchange process.

Ion Exchange Process:

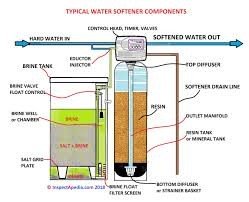

Resin Bed: The core of a softening plant is the ion exchange resin bed, typically made of small, porous beads containing sodium or potassium ions. As hard water passes through the resin bed, the calcium and magnesium ions in the water are attracted to the resin and exchanged with sodium or potassium ions.

Soft Water Output: The water exiting the resin bed is now “soft,” having significantly reduced levels of calcium and magnesium. This soft water is suitable for various applications, including household use, industrial processes, and boiler feedwater.

Regeneration Cycle:

Brine Solution: Over time, the resin bed becomes saturated with calcium and magnesium ions and must be regenerated. During regeneration, a concentrated brine solution (sodium or potassium chloride) is flushed through the resin bed.

Ion Replacement: The high concentration of sodium or potassium ions in the brine displaces the calcium and magnesium ions from the resin, effectively recharging the resin bed with fresh sodium or potassium ions.

Rinsing: After regeneration, the system rinses the resin bed to remove excess brine, ensuring the soft water produced after regeneration is free from excessive salt content.

Post-Treatment:

pH Adjustment (if necessary): In some cases, the pH of the softened water may need to be adjusted to ensure it is stable and non-corrosive, especially if the water is to be used in sensitive applications like boiler feedwater.

Corrosion Inhibitors: For certain industrial applications, corrosion inhibitors may be added to protect piping and equipment from potential corrosion due to the change in water chemistry.

Applications:

Our Softening Plants Systems are versatile and can be customized for various applications, including:

Residential Use: Providing soft water for households to prevent scale buildup in plumbing, extend the life of water heaters and appliances, and improve soap and detergent efficiency.

Commercial and Industrial Use: Softening water for use in hotels, hospitals, laundries, and manufacturing facilities, where hard water can negatively impact operations and equipment lifespan.

Boiler Feedwater: Softening water used in boilers to prevent scale formation, which can lead to energy inefficiency, reduced heat transfer, and potential boiler failure.

Advantages:

Efficient Scale Prevention: Our systems effectively prevent scale buildup, reducing maintenance costs and extending the lifespan of pipes, appliances, and industrial equipment.

Customizable Solutions: We design softening plants tailored to your specific water hardness levels and usage requirements, ensuring optimal performance and cost-effectiveness.

Low Maintenance: Our systems are designed for easy operation and minimal maintenance, with automated regeneration cycles and user-friendly controls.

Sustainability: By preventing scale buildup, our softening plants help reduce energy consumption and prolong the lifespan of equipment, contributing to more sustainable water management.

Our Softening Plant Systems provide dependable, high-performance water softening solutions for any size of operation. Whether for domestic, commercial, or industrial applications, our solutions ensure that your water is hardness-free, safeguarding your infrastructure and increasing overall efficiency.