Our Remineralization System service provides essential solutions for restoring vital minerals to treated water, ensuring it meets quality standards for taste, safety, and functionality in various applications.

Process Overview:

Remineralization is the process of reintroducing important minerals such as calcium, magnesium, and bicarbonates back into purified water via techniques such as reverse osmosis (RO) or distillation. These procedures, while highly successful in removing pollutants, deplete water of essential minerals. Remineralization restores these minerals, thereby increasing water quality, stability, and flavor.

Details:

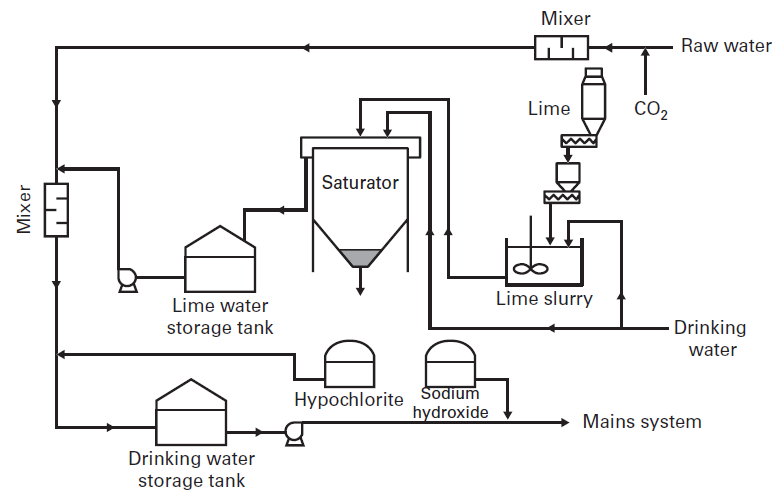

Calcium and Magnesium Addition: When demineralized water is generated, it is frequently excessively pure for practical usage and deficient in important minerals. Our technology typically adds controlled amounts of calcium carbonate (CaCO₃) or magnesium oxide (MgO) to water. These minerals are injected into the water via a contact chamber or mixing tank, where they dissolve and increase the water’s hardness to the appropriate level.

Bicarbonate Addition: Bicarbonates are frequently used to balance the pH and alkalinity of water, preventing it from becoming overly acidic, which can cause corrosion of pipes and equipment. Sodium bicarbonate (NaHCO₃) is frequently utilized in this technique.

Blending Techniques: In some circumstances, remineralization can be accomplished by combining demineralized water with a controlled amount of untreated or partially treated water that contains minerals. This technology is commonly utilized in large-scale water treatment facilities where mixing can be effectively managed.

pH Adjustment: To ensure that the remineralized water is not too acidic or alkaline, our system contains pH monitoring and control features. By carefully managing the pH, we ensure that the water is safe to consume, use in industry, or in other applications.

Carbon Dioxide Injection: In some systems, carbon dioxide (CO₂) and calcium carbonate are pumped into water to form calcium bicarbonate solution. This method improves the stability of remineralized water and aids in achieving a balanced mineral content.

Applications:

Our Remineralization Systems are vital in several applications, including:

Drinking Water Production: Ensuring that purified water has the necessary minerals for health benefits and improved taste, making it suitable for consumption.

Industrial Processes: Providing water with specific hardness levels required for various manufacturing processes, such as in food and beverage production.

Desalination Plants: Adding minerals back into desalinated seawater to make it safe and palatable for human consumption.

Aquatic Systems: Maintaining the health of aquatic environments by ensuring water has the right mineral balance for aquatic life.

Advantages:

Improved Water Quality: Remineralization enhances the taste, texture, and safety of purified water, making it suitable for various applications.

pH Balance and Stability: Our systems ensure that remineralized water is pH-balanced and chemically stable, reducing the risk of corrosion and scaling in distribution systems.

Customization: We tailor our systems to meet the specific mineral requirements of your water, whether for drinking, industrial, or environmental use.

Compliance: Our remineralization processes help meet regulatory standards for potable water, ensuring safety and quality.

With our Remineralization System, you can be confident that your water will contain the proper mineral balance to fulfill your demands. Our experience guarantees that the water is not only clean, but also healthy and appropriate for its intended usage.